The CS-Vison 2.0 identification and detection algorithm module has hundreds of built-in algorithms to meet various visual inspection needs. Algorithm software in the process of appearance defect detection without programming, selection of algorithms, set parameters to achieve the classification of different NG products to reject, a full range of coverage of inductor production process may occur in all types of defects.

In response to customer demand, in the image recognition process, the special light source of Transcend AOI is used to brighten the entire image to ensure that all kinds of subtle defects in the inductor can be clearly presented, which is convenient for the visual recognition software to carry out feature extraction, and to improve the inspection efficiency and accuracy.

Detection Effect

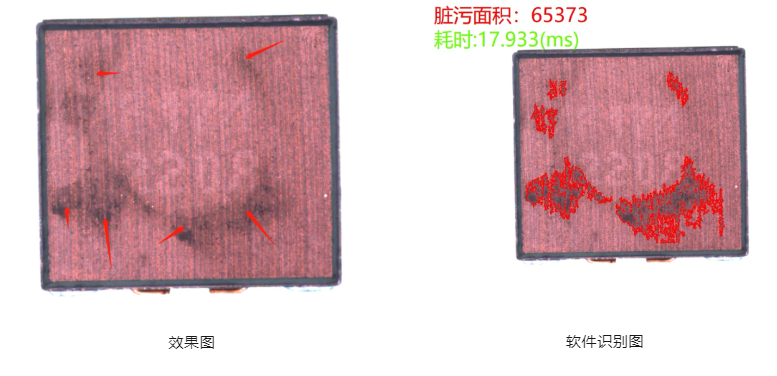

Dirty

In the program, for the inductor surface dirt detection found that the defects and the background chromaticity is similar, in the ordinary light source, a large area of dirt can be successfully detected, the contrast of light dirt is not obvious, in the use of AOI special light source, small pieces of dirt can be clearly distinguishable.

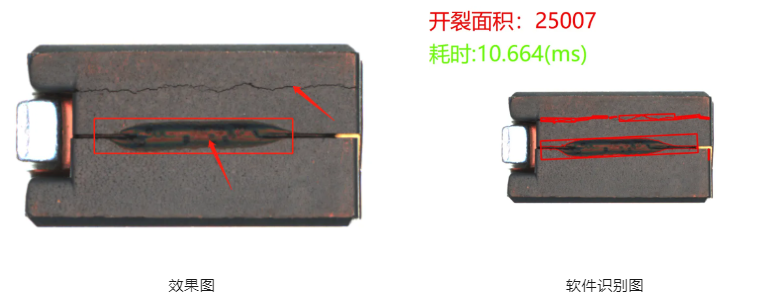

Crackles

In the program, for the product appeared in the upper and lower misalignment and crack two kinds of defects can be detected at the same time, the upper and lower misalignment need to lighten the whole surface to identify the contour position can be, for the large cracks, the use of ordinary light source can also be clearly identified for the small cracks, the use of AOI after the contrast of the special light source is more obvious.

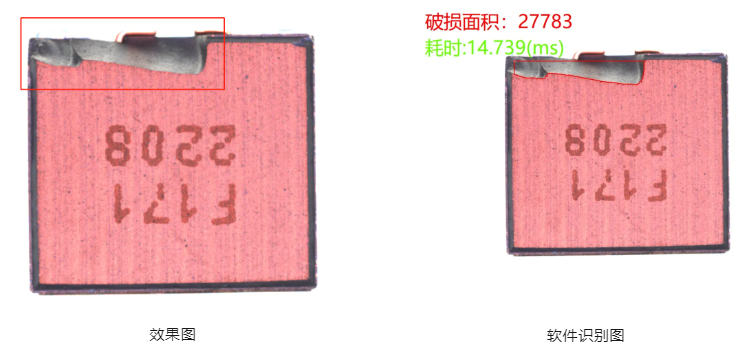

Breakages

Inductor production process, broken defects in six surfaces randomly appear, for large defects, the use of conventional coaxial light source or AOI special light source effect difference is not obvious. For small pieces of broken areas, the contrast of the conventional coaxial light source is not obvious, it is recommended to use AOI special light source.