Various types of defects in the product are clearly visible, and when combined with automated production equipment, it can realize automatic detection of wrong materials, mixed materials, inverted characters on the workpiece, and automatic rejection of defective products. Through the application of machine vision inspection technology, it solves the problem of omission and misjudgment in detecting minor defects with naked eyes, and greatly improves the detection accuracy. Moreover, Chuangshi Automation screen printing defect detection imaging program can set different sorting conditions for different kinds of screen printing defects according to the inspection requirements, in order to meet the screen printing quality inspection requirements of different batches of products.

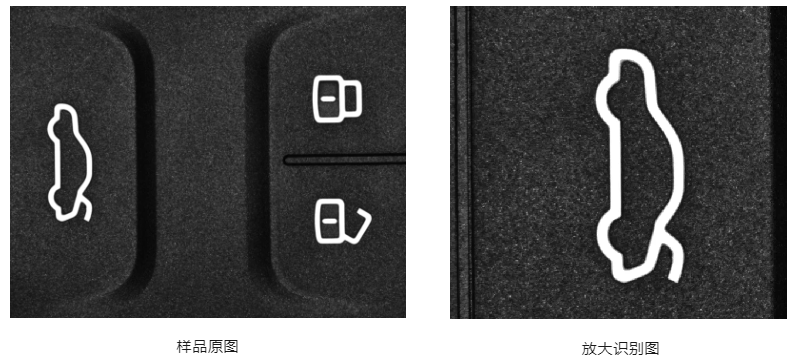

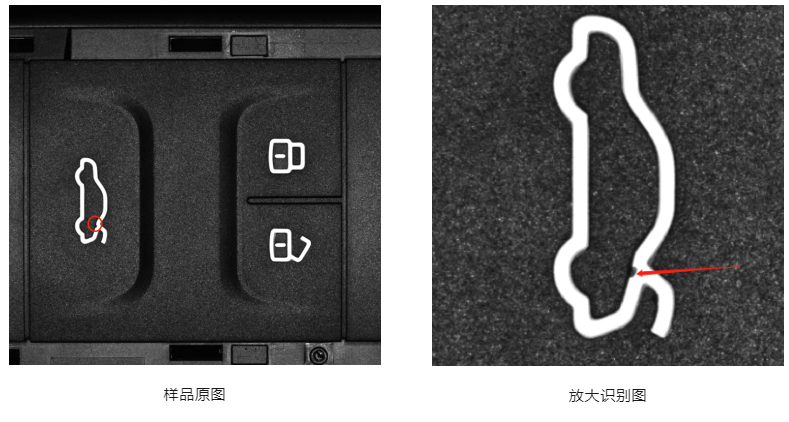

Detection Effect

Poor silkscreen

Poor silkscreen

Poor silkscreen

Poor silkscreen