1、Camera: 500W black and white camera;

2、Lens: 25MM Transcend FA lens;

3、Light source: Chuangshi optical imaging module;

4、Software: Chuangshi vision professional software CS-Vison2.0 recognition detection algorithm module.

Screw samples are cylindrical with curved surfaces. Conventional lighting method will be tilted camera lens to obtain a small part of the defects, need to take pictures several times or rotate the sample, the program uses the Chuangshi optical imaging module, can be divided into four parts of the product's inner side wall, a single imaging. Both improve the detection efficiency and detection accuracy, the outer wall of the scratches, foreign objects, fit gap can be directly detected.

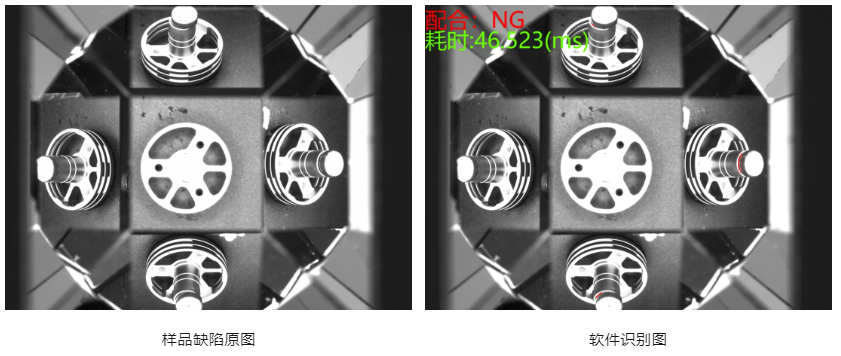

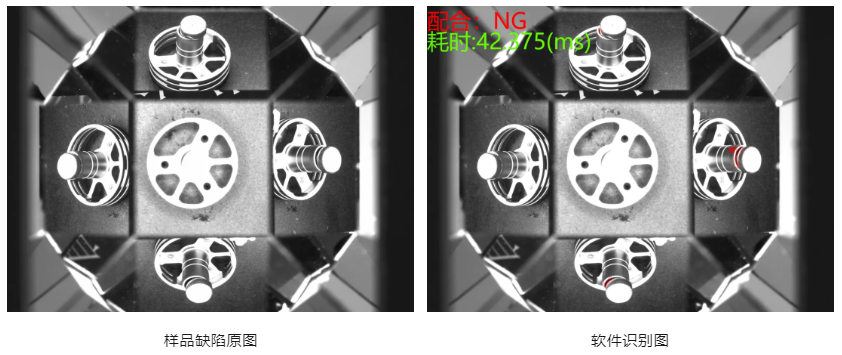

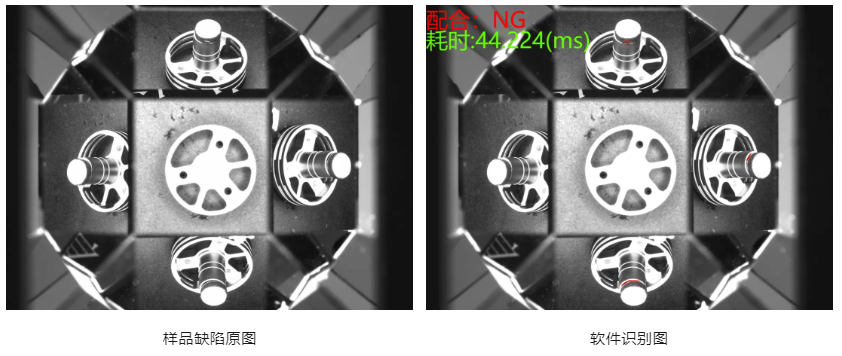

Comparison of Detection ffect

Scratch

Mismatch

Mismatch

Mismatch