Detection Difficulties

The sample is a 30*10mm metal plate, the sample size is smaller, in which the possible defects are more subtle;

The surface of the sample is golden in color, with serious reflection, when subjected to light changes, shadows, reflection problems, the real defects are masked, and a few defects are easy to merge with the background leading to unrecognizable;

The sample material is relatively rough, the position and angle in the field of view is random, and the location, size, shape and depth of the defects are irregular, making the visual inspection process more difficult.

Inspection Solution

For ceramic chip appearance defect detection, Chuangshi Automationceramic chip appearance inspection program chooses Chuangshi professional software CS-Vison 2.0 to identify the detection algorithm module with Chuangshi coaxial light source and brand cameras to form a complete automated visual inspection system.

On the Choice of Software

CS-Vison 2.0 professional software identifies the detection algorithm module for easy operation, and the communication protocols are docked with many mainstream brands of equipment in the industry and are maturely applied. Combined with the automated production equipment, the inspection standard, production beat, flow rate and other parameters can be adjusted according to the actual production plan, for scratches, silver leakage, indentation and other defects can be effectively detected, there is no risk of omission, wrong inspection.

Hardware Selection

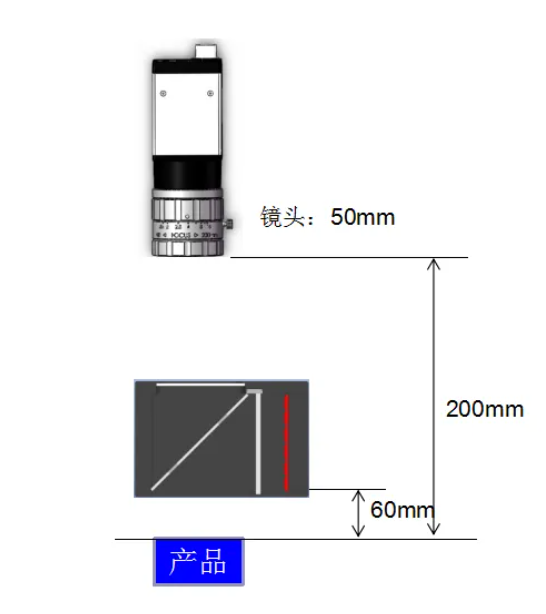

Choose a color camera, irradiation from the top of the product, restore the product color, with high-resolution lens to meet a variety of different needs for dynamic adaptation.

In the Choice of Light Source

The use of reflective surface defect detection for the choice of coaxial light source, the light source uniformly irradiated in the product end face, the surface is bright, defects in the location of the color difference with the normal surface, the overall end of the reflective surface due to differences in the characteristics of the background and the formation of a high degree of contrast.