In Terms of Hardware Selection

Inspection system by combining with automated production line, image acquisition components and light source position linkage, the product to be inspected is placed horizontally, the inspection surface is facing upward in a straight line movement, the line scanning camera is tilted at 48 ° to shoot.

On the Choice of Light Source

The program chooses to use tunnel light source (line array). Realize long-distance uniform irradiation, eliminating uneven reflection on the product surface.

In the Choice of Software

The program adopts Trunsight AI intelligent software V1.0 with a large number of built-in preprocessing algorithms, a simple and intuitive graphical interface is easy to use, reducing customer training and labor management costs. During the whole inspection process, the image processing steps and defect detection results are displayed in the interactive interface in real time and saved in the production log, which is convenient for tracing afterwards.

Comparison of Inspection Results

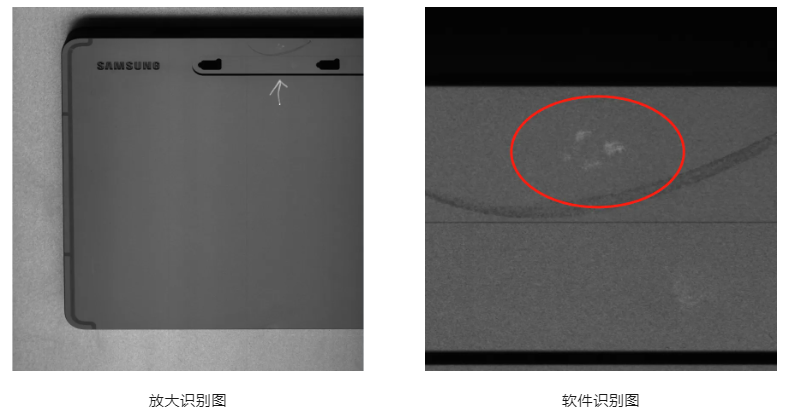

Scratch

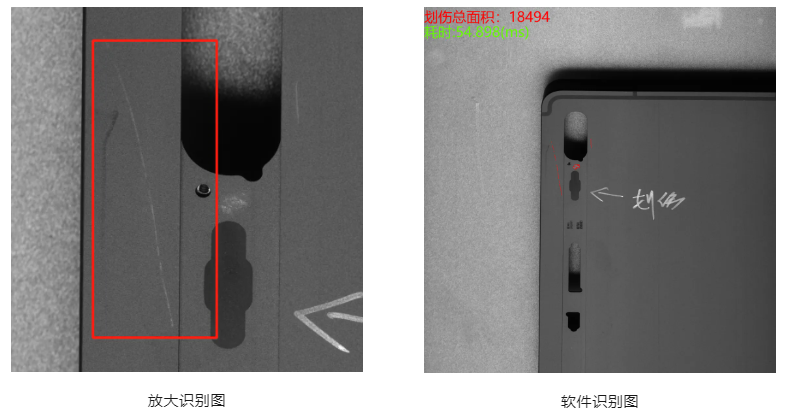

Crush injury

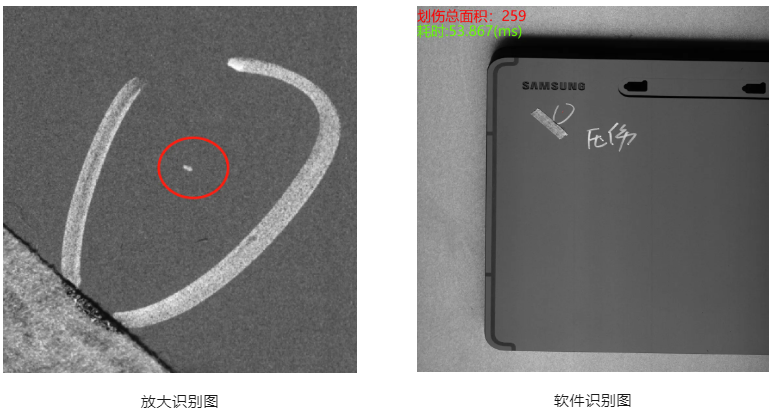

A bright seal