Hardware Imaging: The program is equipped with a 10 million industrial camera with Chuangshi brand line scan lens to obtain high definition images. The coaxial light source is used for illumination, effectively eliminating image ghosting and uniformly illuminating the entire sample to be inspected. With the use of Chuangshi brand industrial controller, light source controller and other visual imaging components, only one station can be set up to detect surface bubble defects, and its features can be clearly imaged, reducing the difficulty of detection. The program with the robotic arm or assembly line, you can complete the automated inspection. Automatic rework for minor defects, serious defects shutdown alarm, to ensure product quality, to achieve lean production.

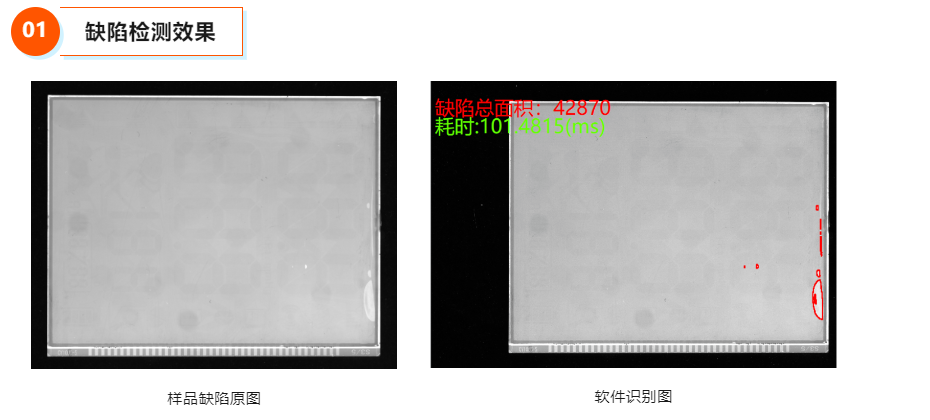

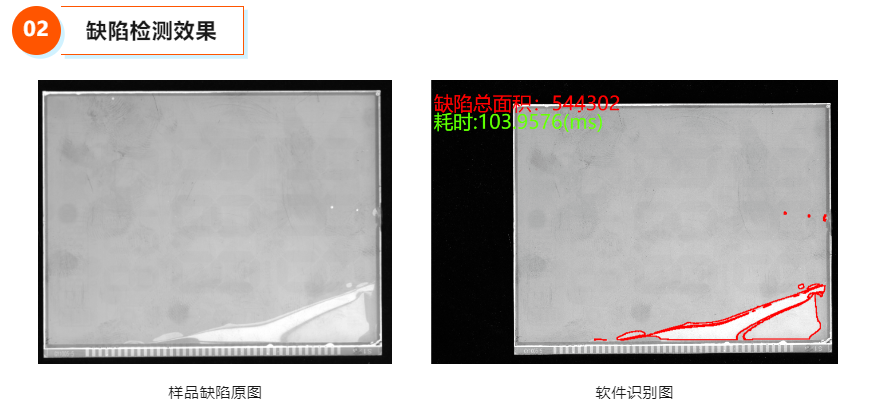

Software nalysis: The CS-Vison 2.0 defect detection algorithm module adopted in the program can easily cope with the strict requirements of display screen manufacturers. After the actual use of customer verification, single detection algorithm takes less than 130ms, can detect 5 products per second, the detection accuracy of up to 0.02mm. not only this, the program can also be widely used in a variety of sizes, types, process segments of the production of the display screen defects detection problems, to achieve 100% on-line detection. Algorithm software customization degree is higher, in the customer site deployment is completed, can quickly solve the corresponding problems, and at any time to optimize the adjustment, help to achieve the product “zero” defects.

Comparison of Detection Effect

With machine vision technology as the core, Chuangshi Automation continuously innovates application scenarios based on industrial vision “defect detection, size measurement, identification and counting, visual positioning”, and introduces a series of vision inspection solutions, which continuously empowers enterprises to automate and upgrade their intelligence. Help enterprises to improve product quality and production efficiency, reduce costs and errors.