After analyzing the samples sent by the customer, the engineers found that the samples had different defects and colors. Through the use of color camera with four-sided shadowless light source on the product for uniform illumination, not only to illuminate the entire product, while restoring the original color of the sample, the sample defects and the original product contrast is obvious. By adopting Trunsign's automated visual inspection solution, all the defects of the samples can be recognized!

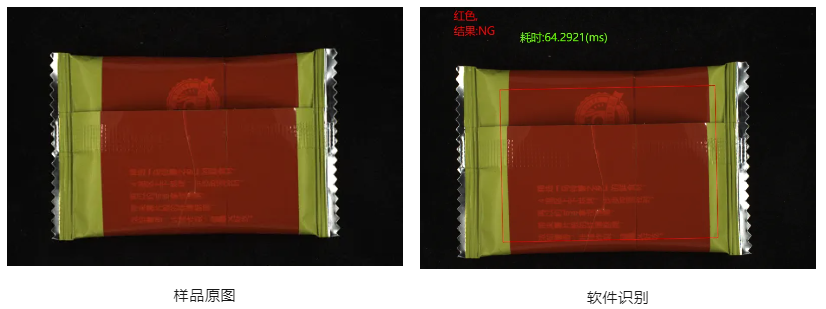

Inspection Effect

Through the use of Chuangshi Automation visual imaging inspection solution, the existing samples are inspected in an all-round way, in which the product defects such as sealing end pressure material, shrinkage, even packet, sealing end foreign matter and other product defects are clearly contrasted with the sample defects, which can effectively help the food production enterprises to reduce the number of personnel in the manual visual inspection position and reduce the production line operation cost.

Back seal defective

Poor sealing ends - shrinkage

Silkscreen error

Silkscreen translocation